As a professional service technician, mechanic, or facility manager, you know you have the knowledge and expertise to do the work, but from a business standpoint, there are other considerations you'll need to better plan and budget time, money and resources.

Overview

- Lube, Oil and Fluid Change Services

- Fuel Management, Extraction and Storage

- Tire Service, Maintenance and Repair

We’ll also cover some shop basics, such as:

- Facility Size, Layout, Bays and Workstations

- Environment: Air Flow, Temperature Control, Ventilation/Exhaust

- Walls, Lighting, Flooring and Storage

- Tools and Shop Supplies

How to Use This Guide

What Type of Service Shop are You Operating?

Decide what scope of services your shop will offer. This can include:

- Auto Repair Shop

- Quick Lube and Oil Change Shop

- Heavy-Duty Truck Service Shop

- Tire Maintenance and Repair

- Combination

Once you’ve established the scope of your service offerings, start to consider your shop facility basics.

Facility Basics To Consider When Building Your Automotive or Heavy-Duty Truck Repair Shop

- Facility Size and Square Footage

- Bays and Workstations

- Fuel, Fluid and Oil Management and Storage Systems

- Waste Storage and Maintenance

- Storage Closets and Designated Areas for Tools, Equipment and Shop Supplies

- Office/Admin Space and Employee Break Area

- Restrooms and Utilities

- Customer Service Areas and/or Waiting Rooms

Walls, Flooring, Storage and Lighting

Wall Material and Wall Storage

You’ll want to choose repair shop wall storage that functions well with the type of material you choose to cover your walls. Consider layout and any mixed surfaces. For instance, one wall may be brick or cinder block; another, drywall. Another may have large bay windows and may only be compatible with ceiling storage units or high shelves.

Auto Service and Repair Shop Flooring

Consider what type of flooring you want to install in various areas of your shop. Options range from interlocking to floating floor tiles and various types of epoxy and concrete coatings, as well as DIY mechanic shop floor paint. High-traffic, low-pile carpet may work for office/admin and customer service areas.WATCH: Warehouse Epoxy Flooring for Ford Dealership in NJ

Workshop and LED Shop Lighting

Your auto shop should have general overhead lighting as well as task-specific lighting to oversee important work areas, like bays and workstations, customer service center/counter/desk, and office/admin space.

In addition, you’ll want to make sure you have a range of rechargeable battery-powered LED work lights for your mechanics and service techs to use to ensure workplace efficiency, safety and well-being, and optimal performance.

LED work lights include:

- LED Under Hood Lighting

- Floor Lamps and Lighting

- LED Rechargeable Headlamps, Straight Arm and Articulating Work Lights

- Stick Lights, Laser Pointers and Spotlights

- Oil Change Pit Lighting

LEARN MORE:

Environment: Air Flow, Ventilation, Exhaust and Temperature Control

You’ll want to make sure your auto repair and service facility is up to code and also comfortable for your employees and customers.

Think about your doors and windows, and how your shop will manage air flow with proper ventilation and vehicle exhaust systems, as well as occupancy load monitoring, environmental and temperature control. Carbon Monoxide (CO) fumes are dangerous and you need to remove these fumes properly from your shop.

When you’re trying to find the best venting solutions, you may face these familiar challenges:

- Finding the perfect product for a new build or upgrade

- Creating climate-controlled work environments

- Exhaust/fume management

- Shop management

- Product support

- Tech retention

For more information on vehicle exhaust extraction systems, check out our

EuroVent Division

Auto Shop Equipment for Bays and Workstations

Equipment to consider for bays and workstations include:

- Vehicle Lifts

- Air Compressors

- Jacks, Jack Stands and Pole Jacks

- Oil & Fluid Handling: Oil Drains, Oil Caddies, Extraction Pumps, Changing Stations

- Battery Charger and Jumper

- Tire Taxi/Cart/Dolly and Floor Stands

- TPMS Solutions: Diagnostics, Tools, Tire Valves and Accessories

- Engine Hoist

- Brake Lathe

- Strut Compressor

- Air Conditioning Machine

- Press

- Task Lighting: Spotlights, Headlamps and Under Hood

- Service Parts and Supplies

Technician and Mechanic Tools and Shop Supplies

Tool Storage

Based on your business objective, facility layout, number of techs, bays and workstations, you can determine your tool storage needs and preferences.

START YOUR CHECKLIST:

Service Shop Supplies, General Supplies, and Cleaning Supplies

In addition to service-specific tools and supplies, you'll also have to consider general facility supplies. This will include generic office, business, and cleaning supplies, as well as specialized supplies relevant to your service offering, such as:- Auto Service Reminder Stickers

- Hose Reels

- Floor Stands and Accessories

- Automotive Interior Protection

- Steering Wheel Covers

- Floor Mats

- Seat Covers

- Tire Storage Bags

- Gear Shift Knob Covers

- Parts Return Bags

Service Parts and TPMS

JohnDow Dynamic Service Parts

Our Dynamic line offers a full line of automotive repair service products, service kits, and back shop supplies for any professional repair facility.

Oil, Fuel and Fluid Management, Extraction, and Storage

Why Do I Need an Oil, Fuel, and Fluid Management System?

Fluid management is critical for both automotive and heavy-duty truck operations for reasons of cleanliness and safety, business efficiency, and industry compliance. A well-maintained fluid management system will track the dispense of oils, antifreeze, coolant and all other vehicle fluids, resulting in reduced costs and improved operational productivity and efficiency.

How Do I Properly Dispense, Store, and Manage Oil and Fluids?

You’ll need to address your fluid storage, management, and extraction practices and be sure you have the equipment to support your operation’s needs.- You need to inventory, store, and manage your fluids well to maximize productivity and profit

- Strictly manage Oil and both unleaded and diesel fuel separately from other fluid types

- Engine Oil

- Unleaded Fuel/Gasoline

- Diesel Fuel

- Engine Coolant

- Transmission Fluid

- Brake Fluid

- Differential Fluid

- Power Steering Fluid

- Hydraulic Clutch Fluid

- Window Washer Fluid

How to Comply with Federal Hazardous Material Regulations

Fuel management is regulated by The Occupational Safety and Health Administration branch (OSHA) of the US Department of Labor. Two certifying bodies ensure products meet those regulations: UL and UN/DOT.The Underwriters Laboratories' UL listed mark signifies a product meets the UL’s nationally recognized Standards for Safety. Fuel caddies, fuel carts, and gas tanks labeled with the UL mark have been inspected and approved.

The US Department of Transportation (DOT) and the United Nations (UN) have set forth specific guidelines companies must follow regarding the transportation and storage of certain hazardous materials.

More specifically, the DOT approves storage tanks and transport devices for gasoline and AV gas traveling over public roadways. These requirements are not necessary for but are also approved for the storage and transport of diesel fuel.

-

NEED TO KNOW: What’s the major difference between UL Listed fuel

caddies and UN/DOT approved fuel caddies?If you need to temporarily store fuel in a shop setting, like when replacing a fuel pump, you’ll need a UL listed fuel caddy. If you need to transport fuel over the road, like going on a weekend ATV trip, you’ll need a UN/DOT container.

Proper fuel handling and management is serious business. An accident can ruin your entire business investment. Educate yourself on the commonly unknown dangers of fuel mismanagement.

What You Don’t Know Can Burn You!

How to Avoid Unknown Dangers of Handling Fuel in Your Shop Download your free eBook

THE REGULATIONS YOU NEED TO KNOW:

The products to consider when you custom-build your inventory based on your shop facility’s needs will likely always include oil and fluid handling equipment and fuel handling equipment.

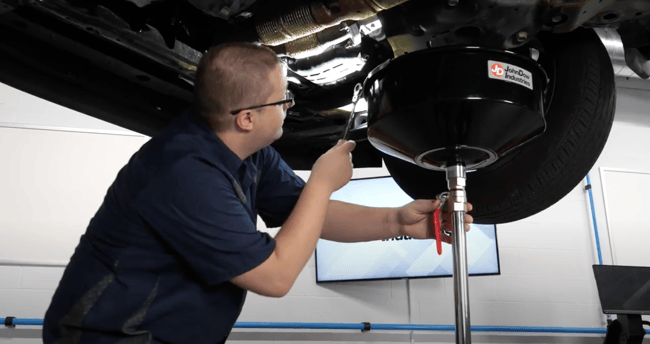

Oil & Fluid Handling Equipment

Your oil drains and fluid handling equipment should be of quality workmanship with features to make your job easier, safer and more efficient. Features and materials to consider include steel and poly-constructed oil drains with self-evacuating, pump assist, or low-profile models.

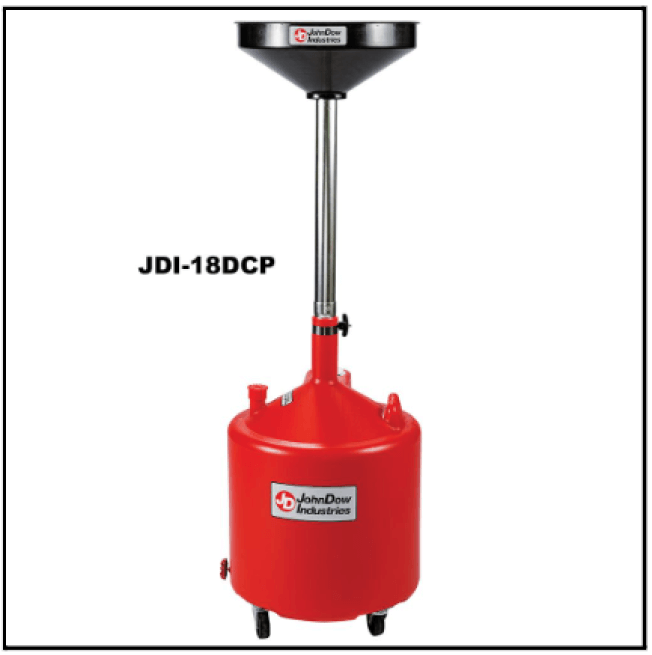

- Oil Drains: Economy, Pump Assist, Self-Evacuating, Low-Profile

- Fluid Evacuators, Fluid Drains and Combination Drains

- Oil & Fluid Handling Parts and Accessories

ON WATCH: How to Choose the Best Oil Drain with JohnDow Industries

Do I Need a Fluid Evacuator in My Shop?

You’re thinking about getting a fluid evacuator for your business.However, you want to know whether you’ll get any use out of it before you spend the money.

Here’s how to decide if you need a fluid evacuator in your shop.

How Does a Fluid Evacuator Work?

Most fluid evacuators use a venturi valve that hooks up to shop air to create a vacuum of pressure to pull fluid out of a vehicle. Some DIY-type fluid evacuators come in a hand-pump style that creates a pressure vacuum to remove fluids, like the one below.

Why Do I Need a Fluid Evacuator?

You need a fluid evacuator in your shop if you do oil changes or work with other fluids such as coolant, transmission fluid, brake fluid, differential oil, and power steering fluid.

You should have a fluid evacuator if you tend to come across damaged or cross-threaded drain plugs from a previous shop’s work. In these situations, evacuating the oil will save you from paying for an oil pan that was damaged by another shop.

It’s also good to have a fluid evacuator if you work on import vehicles such as BMWs, Land Rovers, and Jaguars. Many European manufactured vehicles don’t use drain plugs anymore, so you must evacuate oil through the dipstick.

ON WATCH: How Fluid Evacuators Work and How to Choose Yours

What Are Some Other Fluid Evacuator Applications?

Fluid evacuators aren’t just for cars, trucks, vans, and SUVs. You can use them to work on motorcycles, ATVs, boats, jet skis, tractors, generators, and off-road equipment.

Do I Need a Fluid Evacuator in My Shop?

If you deal with a lot of different fluids, see a lot of damaged drain plugs, or work on imported vehicles, a fluid evacuator is a must-have.

How Do I Choose an Oil Drain?

When you’re shopping for an oil drain, take a minute to ask yourself a few questions:

-

How many oil changes are done in your shop daily?

This will determine how big your oil drain needs to be. -

How do you store waste oil, and do you have a suction pump?

This will lead you to the best oil drain style: self-evacuating or pump-assist.

-

Do you work with expensive vehicles?

This will help figure out whether to go with a poly or steel oil drain (You could damage cars with a steel version).

What’s the Best Scenario for a Pump-Assist Oil Drain?

You can make the most out of a pump-assist oil drain if you have a waste oil tank with a pump already in your shop. This type of drain lets you hook up a suction hose directly to a full oil drain and transfer oil from the drain to the waste oil tank. Shop air usually runs the suction pump.

Pump-assist oil drains vary in size from 8 gallons for a smaller shop with a couple of bays to 27 gallons for a high-volume operation with multiple bays.

What’s the Ideal Situation for a Self-Evacuating Oil Drain?

A self-evacuating oil drain would be more efficient if your shop doesn’t use a pump. This drain uses shop air to pressurize the oil drain when it’s full of used oil to push the oil out of the drain and into a waste oil tank or 55-gallon drum.Self-evacuating oil drains require a lower initial investment and fewer pieces of equipment. Various sizes are available to meet your shop’s needs.

The Bottom Line

If you already have a waste oil tank with a suction pump in your shop, a pump-assist oil drain would be the best route. If you don’t have a suction pump, a self-evacuating oil drain will serve you better.Fuel Handling Equipment

Your fuel handling products should meet a few requirements. Most importantly, all fuel handling products should be certified to meet or exceed OSHA regulations so you can safely handle fuel in your shop. Your top concerns should be safety, effectiveness, and affordability when it comes to all aspects of fuel dispensing, transport, and storage.- UL Listed Fuel Caddies

- UN/DOT Approved Portable Fuel Stations

- Diesel Carrytanks

- DEF Delivery Systems

- UN/DOT Approved Poly Fuel Caddies

- Fuel Handling Accessories and Parts

Why Can’t I Put Gas in a Diesel Caddy?

There are big differences between gasoline and diesel fuel, and the two definitely don’t play well together. Here’s why.You have to consider the main difference between these two fuel types: molecular weight. Diesel fuel is heavier than gasoline, lending to its density and viscosity. It responds to a higher ignition temperature and flashpoint.

Gasoline, on the other hand, responds to a lighter ignition temperature and flashpoint.

Due to differences in fuel type physical properties, mixing diesel and gasoline triggers safety and operational issues to arise with temperature control, engine efficiency, and storage.

Improper storage of flammable and combustible liquids such as diesel and gas can lead to fires or explosions. The best way to ensure safety is to store gas in a UL Listed gas-designated caddy that meets Occupational Safety and Health Administration (OSHA) standards.

- To prevent accidental mishaps in your shop, keep an adequate inventory of fuel handing equipment for both types of fuel so shop technicians and operators aren’t tempted to reach for one or the other out of necessity.

- Educate shop staff and technicians on the importance of proper fuel handling and separation, including your shop’s designated storage devices and policies.

- To avoid mixing and contamination, clearly label your fuel storage devices. A caddy needs to be dedicated to a specific type of fuel. Any container used to store gas or diesel must be properly marked with the stored fuel. Generally, gas is kept in a red caddy, and diesel is stored in a yellow caddy. This allows technicians to easily identify each fluid in the shop.

ON WATCH: How to Choose the Right UN/DOT Fuel Caddy for You

What to Know Before Buying a Steel Fuel Caddy

The primary purpose of a steel fuel caddy is threefold:

- Transfer fuel from the tank

- Store fuel during the repair process

- Put fuel back into the tank after the repair is done

A lot of steel fuel caddies on the market look the same but are sold at various prices. Here are the things you need to look for to make the right choice for your shop.

Safety

Safety must be your number one priority. You should look for a UL-listed steel fuel caddy. The tank and the pump will carry separate approvals. This certification ensures the equipment was tested for stability, strength, and fire safety.

Size

The size you need depends on the vehicles you normally service. A 25- or 30-gallon steel fuel caddy is sufficient for most cars and light trucks. If your primary purpose is removing fuel and storing it, you’ll need a larger size.

Pump

Your fuel caddy should come equipped with a two-way rotary pump or a UL listed air-operated diaphragm pump rated for fuel. You must also think about transfer capacity. A good rotary pump should transfer about seven gallons a minute when turning at a normal rate.

Fuel

You must dedicate each fuel caddy to a specific type of fuel to avoid mixing and contamination. Gasoline goes in red caddies; diesel is stored in yellow caddies. If you service cars that use E85 ethanol fuel, make sure your fuel caddy is E85 compatible.

Filter

Since you need to avoid putting contaminated fuel back into a vehicle you just serviced, you should use a fuel caddy with a filtration system. In-line filters come standard on some fuel caddies. You can also buy filter kits separately.

The Bottom Line

Considering safety, size, pump, fuel, and filter before your purchase will make your decision easier.

Fuel Management Parts and Accessories

Don’t forget about your parts and accessories options, including everything related to fuel line fittings and assortments:

Fuel Lines: Fittings, Adapters, Connectors, and Clamps

See the difference:

Wrapping it All Up

There’s a lot to consider when venturing out to open your own automotive or heavy-duty truck repair service facility. With proper preparation, planning, allocating, and budgeting of resources, you can make it happen.

Always keep the scope of your service offerings and the size and scale of your business in mind – with room for expansion. That will lay the foundation for your shop layout and design, progressing you to the next steps of facilitating your shop tools, equipment, and supplies.

JohnDow Industries will proudly provide you with the best quality shop equipment available. Our experts are ready to help answer any of your questions regarding shop equipment options to best suit your needs.